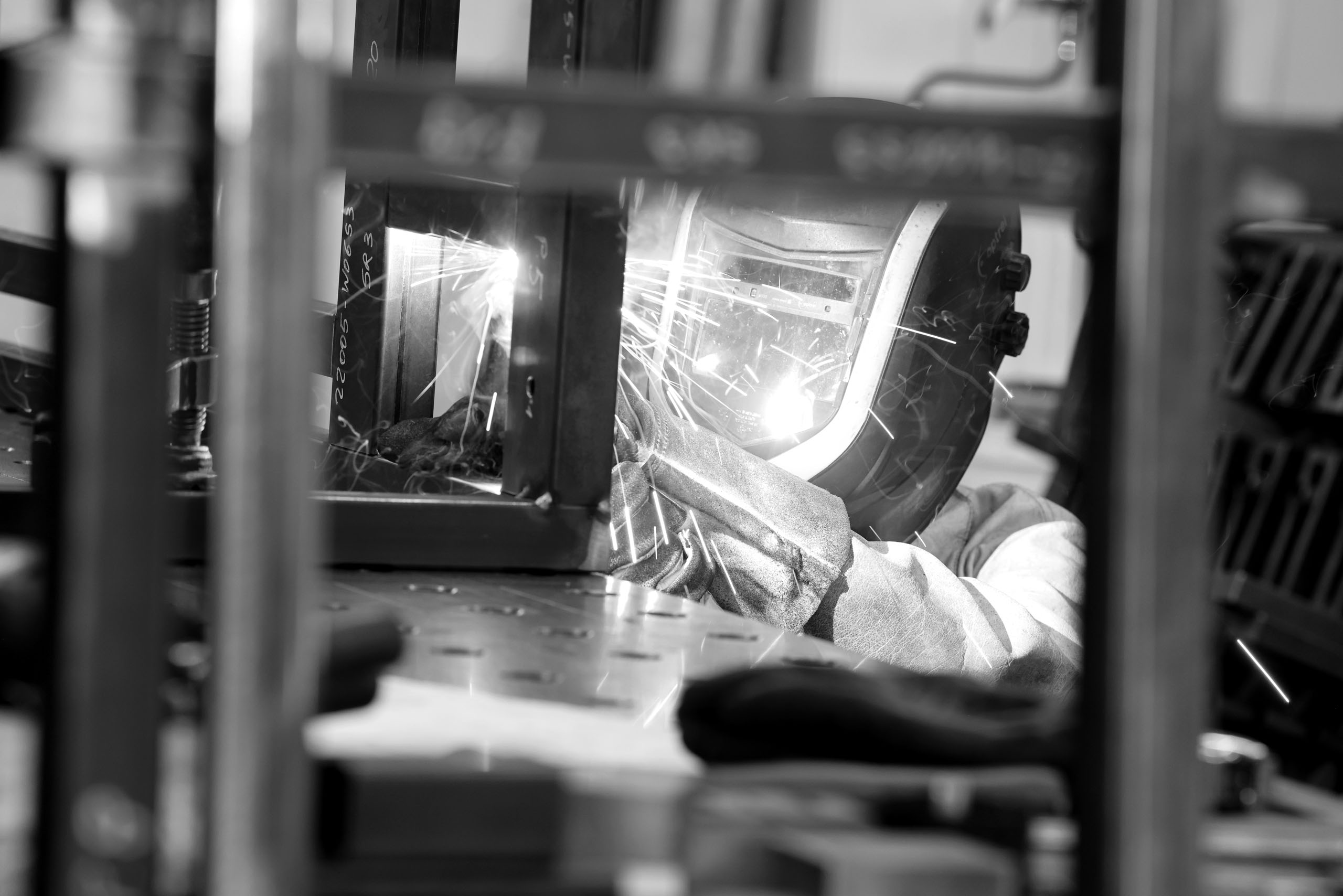

In the metal-workshops, state-of-the-art machinery and technologies are used to create a variety of metal frame constructions, sheet metal panels, locking and interlocking devices as well as climate control compartments made of steel, stainless steel, aluminum and other non-ferrous metals. CNC-controlled machines guarantee constant maximum precision and minimum manufacturing tolerances.

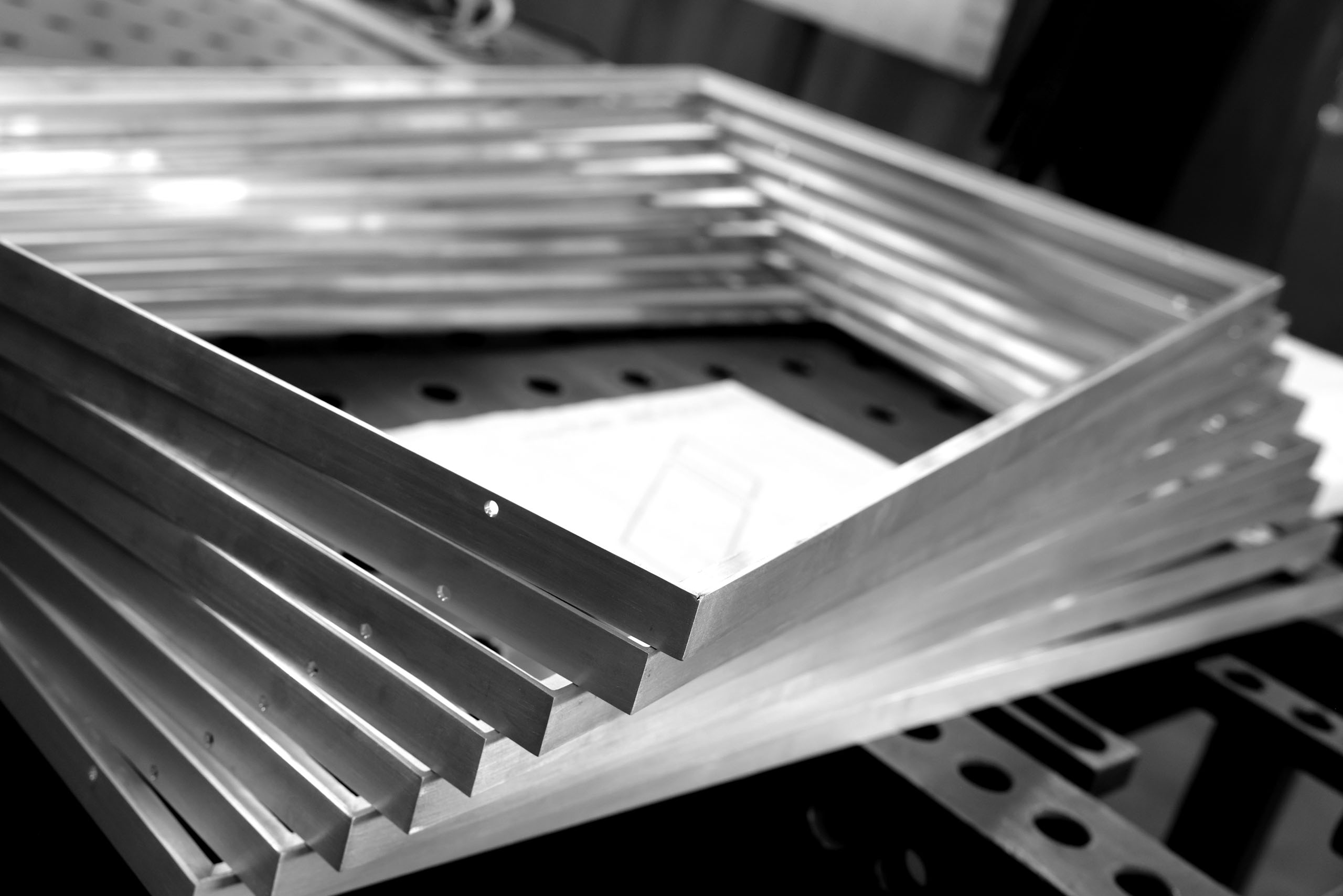

In the Metal Workshops, our own laser-cutting machinery keeps the process completely automated and free from dependency on sheet metal suppliers. Our equipment can process sheet steel in dimensions up to 3000 mm x 1500 mm and sheet thicknesses up to 12 mm.

Data transfer is specially tailored to the machine and our CAD architecture software where the 3D CAD data is automatically turned into sheet metal patterns. The patterns are saved and applied to an icon library of the laser software, and so, within minutes, the metal sheets are cut and available for manufacturing.